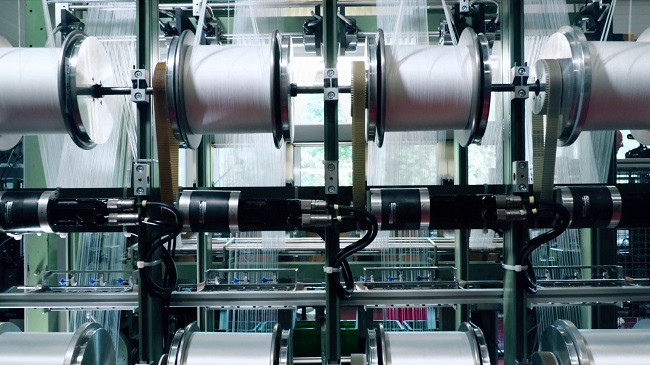

Despite the numerous challenges and supply chain disruptions in the textile industry – the textile machinery makers strive to bring the innovations and developments in the technology. Manufacturers have developed technological solutions that increase product and process efficiencies to counter the ongoing challenges. With the continuous innovation, more efficient machinery is being produced which consumes less energy, water and other raw materials and gives maximum output.

The textile & apparel industry has undergone a significant technology adoption in recent years. Technological advancements such as automation, robotics, and artificial intelligence have been integrated into the manufacturing process.

Technology, with advanced featured, adoption has led to a noteworthy advancements in textile production, resulting in increased efficiency, sustainability, and innovation in the textile industry. Development of technology can help the industry healing the current wounds, it can open a new window for the textile and apparel industry.

When to Adopt Technology:

The textile industry currently focuses on reductions in energy, chemicals and water usages both in the input and process phases. New developments in the machineries usually provide opportunities to efficient textile processing. By selecting appropriate technologies, companies can stay competitive and help the environment. One serious advantage of selecting right technology is that it helps your business reduce risk, you can make use of resources effectively.

It is not enough of the adoption of technology only; when exactly we adopt the technology is also reasonably important. Effectiveness of the investment (adoption), to a some extent, critically depends on the timing of adoption.

Figure 1: Technology Adoption Life Cycle and Its Impacts on Competitiveness.

a) Innovators: The first group of people to adopt a new idea and this group also generates ideas. They adopt and stay ahead of other people. Countries like Germany, USA, Italy, etc are renowned for their precision engineering and technological advancements. They have a long history of textile manufacturing and have embraced modern textile technologies, and have developed innovative machinery, software, and materials for the textile industry.

b) Early Adopters: They gain mentionable benefits out of the adoption for being early adopters. China, UK and Turkey for an example, are few of the early adopters. They heavily invest in the new textile technologies that brings good prices of their manufacturing products.

c) Early Majority: This group also some sort of advantage of adoption of technology. Bangladesh, India, Pakistan have a diverse textile industry and are known for their traditional textile production methods. However, these countries have also embraced textile technology to modernize production processes, improve productivity, and develop innovative textiles.

d) Late Majority: They last category of adopters who implement a new idea quite lately. This adoption sometimes becomes detrimental as new innovation may come in the market. When it comes to the late majority of adoption, several factors contributing to late adoption; it can vary and may include economic constraints, lack of infrastructure, limited access to technology, or a focus on traditional textile production methods.

e) Non-adopters/Laggards: They don’t adopt new idea or technology – is an extreme case, not simply seen in practice. In the market of a continued high competition, we should be adopting the new technology as the early adopters, or at least as an early majority that can hold us competitive.

Figure 2: Quality enhancement and cost reduction due to right technology adoption.

Setting a strategy for Technology Adoption:

1. Identifying business objectives: Prior to adopting a new technology, it’s important to identify clear business objectives, and how technology adoption can help achieve them. This may involve reducing costs, increasing production capacity, improving quality, or enhancing sustainability.

2. Evaluate existing infrastructure: Evaluate the existing infrastructure, preparation, workflows, and processes to identify gaps and areas for improvement.

3. Reviewing available options: Once business objectives have been identified, it’s important to assess available technology options and their potential impact on the business. This may involve researching emerging technologies, evaluating potential partners or vendors, and considering factors such as cost, scalability, and compatibility with existing systems (people, capacity, process, market, price and ROI etc.)

4. Having a clear roadmap: After assessing technology options, it’s important to create a roadmap for technology adoption. This should include a timeline for implementation, a plan for testing and evaluating new technologies, and a strategy for managing change and ensuring employee adoption.

5. Investing in learning and development: It is important to invest in training and development for employees to exploit the benefit of the adoption. This may include providing training on new systems and processes, as well as investing in ongoing support and education to keep up with new developments.

6. Measuring and monitoring progress: At last, it’s important to measure and monitor the impact of technology adoption with regard to the business objectives. This may involve setting key performance indicators (KPIs), tracking progress over time, and making adjustments to the technology adoption strategy if so requires.

Factories in Bangladesh generally invest in the machine, are we investing proportionately to the development of people behind the machine – we should also look at this critical component carefully.

A good number of textile manufacturers in Bangladesh however have adopted environmental friendly, and Water Saving Technology to satisfy customers by producing good quality products with the highest ‘cost-to-value’ ratio. Textile technology adoption brings benefits ranging from increased efficiency and quality to sustainability and innovation. It enables the textile industry to stay competitive, meet evolving consumer demands, and contribute to a more sustainable and technologically advanced future.

ITMA 2023 would showcase the latest machinery, equipment, and technologies ranging to spinning, weaving, knitting, dyeing, printing, finishing, and other textile manufacturing processes. It is going to show the state-of-the-art in textile technology that could allow industry to stay competitive by adopting the latest trends of technologies, and explore investment opportunities. –